Column Pipe

Column Pipe Specification

- Coating Type

- UV Resistant Coating

- Connection Type

- Male-Female Threaded

- Diameter

- 32 mm to 250 mm

- Tolerance

- 1% approx.

- Thread Type

- Square Threads

- Temperature Range

- 0C to 45C

- Tensile Strength

- 400 kgf/cm (approx)

- Bend Radius

- Not Flexible, Fixed Form

- Sealing Type

- Rubber O Ring Sealed

- Yield Strength

- Not Applicable (uPVC Material)

- Flexibility

- Rigid

- Product Type

- Column Pipe

- Material

- uPVC (Unplasticized Polyvinyl Chloride)

- Connection

- Threaded

- Shape

- Round

- Standard

- ISI Marked / As per IS 12818

- Surface Treatment

- Smooth Finish

- Outer Diameter

- 32 mm to 250 mm

- Section Shape

- Cylindrical

- Length

- 3 meters or 6 meters (customizable)

- Thickness

- 2.5 mm to 14 mm (varies by size)

- Color

- Blue

- Usage

- Submersible Pump Installation

- Rated Pressure

- UP to 16 kg/cm

- Material Grade

- Food Grade uPVC

- Application

- Borewell, Drinking Water Supply

- Hydraulic Test Pressure

- Upto 20 kg/cm²

- Corrosion Resistance

- Excellent (No Rust/Corrosion)

- Suitable for Potable Water

- Yes

- Lead Free

- Yes

- Burst Pressure

- Up to 50 kg/cm²

- Weight per Meter

- Varies by Diameter (on request)

- Joint Type

- Threaded Coupler Joint

- Reusable Joints

- Yes

- Installation Method

- Screw Coupling

- Environmental Compliance

- RoHS Compliant

- Low Bacterial Growth

- Yes

- Internal Finish

- Mirror Smooth

- Storage and Handling

- Stackable, Lightweight

Column Pipe Trade Information

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About Column Pipe

We are offering here the column pipe that is manufactured to meet any specification or design including those for water lubricated, oil lubricated, or submersible pumping assembly applications. It can be manufactured in flanged, threaded, or flush joint connections along with wall schedules and materials as specified. It is manufactured with varied diameters used to extract and transport fluids. It is the most suitable pipe for submersible pumps offering several more advantages like ease of installation and function over GI pipes. The column pipe is made for long term use.

Exceptional Corrosion Resistance

Designed using food-grade uPVC, our column pipes deliver outstanding resilience against corrosion, rust, and chemical exposure, ensuring reliable operation even in harsh environments. The smooth exterior and UV-resistant coating extend the lifespan and maintain structural integrity-a crucial advantage for potable water and submersible pump installations.

Safety and Quality Assurance

Each pipe is manufactured to meet IS 12818 standards and carries ISI marking, signifying strict adherence to safety and performance requirements. RoHS compliance and lead-free composition guarantee environmental safety and suitability for drinking water supply. The square-threaded, rubber O-ring sealed joints ensure leak-proof connections and easy reinstallation.

FAQ's of Column Pipe:

Q: How are these column pipes installed for borewell applications?

A: The pipes use a screw coupling mechanism with threaded coupler joints and male-female square threads, which allows for easy, secure installation and disassembly. The joints are rubber O ring sealed for enhanced leak resistance.Q: What makes these pipes suitable for potable water supply?

A: Fabricated from food-grade uPVC and lead-free material, these pipes offer a mirror-smooth internal finish to reduce bacterial growth. Their RoHS compliance ensures zero harmful substance leaching, making them safe for delivering drinking water.Q: When should I consider uPVC column pipes over metal pipes?

A: uPVC column pipes are preferred in environments prone to corrosion, rust, and chemical exposure. Their excellent corrosion resistance, lighter weight, and longer lifespan make them superior choices for borewells and submersible pump installations.Q: Where can these column pipes be used apart from borewells?

A: Besides borewell use, these pipes are ideal for drinking water supply systems, agricultural irrigation, and installations where safety, hygiene, and non-corrosive properties are required.Q: What is the maximum hydraulic and burst pressure these pipes can handle?

A: These pipes are designed to withstand hydraulic test pressures up to 20 kg/cm2 and have a burst pressure capacity reaching 50 kg/cm2, ensuring reliable performance in demanding water supply conditions.Q: How does the mirror-smooth internal finish benefit the application process?

A: A mirror-smooth internal surface reduces frictional losses, promotes efficient water flow, and discourages bacterial growth, ensuring a cleaner water supply and improved pump performance.Q: What advantages do reusable joints offer during installation and maintenance?

A: Reusable joints facilitate easy assembly, disassembly, and relocation without damaging the pipe or joint, reducing labor costs and time during installation or repairs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pipes & Fittings Category

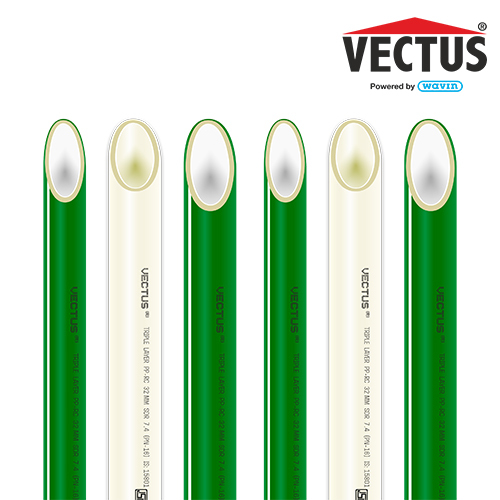

PPR Pipes

Color : Green

Material : Other , Polypropylene Random Copolymer (PPR)

Shape : Round

Standard : Other, DIN 8077/8078

Connection : Other, Socket Fusion, Butt Fusion, Electrofusion

HDPE piping system

Color : Black with blue stripes

Material : Other , High Density Polyethylene (HDPE)

Shape : Round

Standard : Other, IS 4984:2016, ISO 4427

Connection : Other, Butt Fusion, Electrofusion, Compression, Flange

Casing Pipe

Color : Blue

Material : PVC

Shape : Round

Standard : Other, IS 12818

Connection : Other, Female Socketed

Composite Piping Systems

Minimum Order Quantity : 100 Pieces

Color : Black, yellow

Material : Mild Steel, Plastic

Shape : Round

Standard : AISI

Connection : Welding

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese