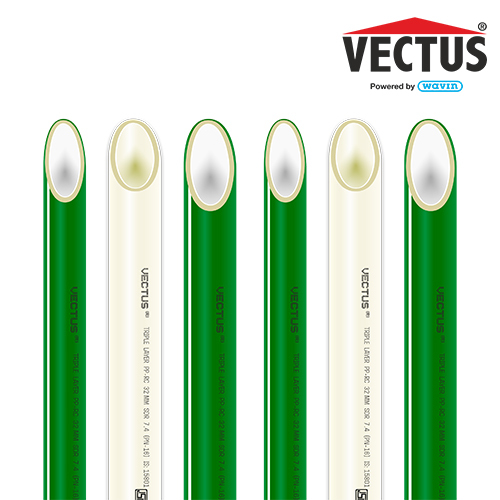

PPR Pipes

PPR Pipes Specification

- Bend Radius

- 5 outer diameter

- Connection Type

- Fusion Welded

- Sealing Type

- Thermal Welding

- Diameter

- 20 mm, 25 mm, 32 mm, 40 mm, 50 mm, 63 mm, 75 mm, 90 mm, 110 mm, 160 mm

- Flexibility

- Semi-rigid

- Tensile Strength

- > 22 N/mm

- Coating Type

- Uncoated

- Tolerance

- +/- 0.3 mm

- Temperature Range

- -10C to +95C

- Yield Strength

- > 20 N/mm

- Product Type

- PPR Pipes

- Material

- Polypropylene Random Copolymer (PPR)

- Connection

- Socket Fusion, Butt Fusion, Electrofusion

- Shape

- Round

- Standard

- DIN 8077/8078

- Surface Treatment

- Smooth

- Outer Diameter

- 20 mm to 160 mm

- Section Shape

- Cylindrical

- Length

- 4 m or custom

- Thickness

- 1.9 mm to 13.7 mm

- Color

- Green

- Usage

- Cold and Hot Water Supply

- Rated Pressure

- PN10/PN16/PN20/PN25

- Application

- Plumbing, Industrial, Chemical Supply, Compressed Air

- Material Grade

- PPR Type 3

PPR Pipes Trade Information

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About PPR Pipes

Exceptional Durability and Performance

PPR pipes are engineered to maintain strength and reliability even in demanding environments. Their semi-rigid form, thermal welding sealing type, and non-flammable nature ensure safe operation across a broad temperature range of -10C to +95C. The combination of excellent chemical resistance and robust mechanical properties guarantees decades of dependable performance.

Flexible Installation Options

These pipes offer several connection methods, including socket fusion, butt fusion, and electrofusion, allowing installers to choose the best fit for specific projects. Suitable for both cold and hot water supply lines, their tolerance of +/- 0.3 mm and standardized diameters make them easy to integrate into diverse plumbing and industrial schemes.

FAQ's of PPR Pipes:

Q: How should PPR pipes be installed for optimal performance?

A: PPR pipes are best installed using thermal welding methods such as socket fusion, butt fusion, or electrofusion to ensure leak-proof joints. Mechanical fittings can also be used for specific arrangements. Proper installation guarantees a long service life and efficient operation.Q: What are the main benefits of using PPR pipes for plumbing applications?

A: PPR pipes offer excellent chemical resistance, non-flammability, and a smooth surface which reduces friction loss. Their service life is over 50 years under normal conditions, making them a reliable choice for both hot and cold water supply systems in homes, industries, and chemical plants.Q: When is it recommended to use PPR pipes indoors rather than outdoors?

A: PPR pipes have moderate UV resistance, so it is advisable to use them indoors or in protected environments to prevent degradation from prolonged sunlight exposure. For outdoor installations, additional protection or covering is recommended.Q: Where can PPR pipes be utilized aside from regular plumbing?

A: Apart from plumbing, PPR pipes are widely used for industrial transport of chemicals, compressed air systems, and supply lines in chemical processing industries due to their robust chemical resistance and flexibility.Q: What installation process ensures the tightest seals in PPR piping systems?

A: Thermal welding, such as socket fusion, provides the most secure and lasting seal, preventing leaks over years of service. This process fuses pipe and fitting materials, resulting in a homogeneous joint.Q: How do PPR pipes withstand chemicals and high temperatures in industrial applications?

A: PPR pipes are manufactured from Polypropylene Random Copolymer, granting excellent resistance to most chemicals. Their rated pressure range (PN10 to PN25) and temperature tolerance (-10C to +95C) make them suitable for transporting aggressive substances in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipes & Fittings Category

ASTM piping system

Standard : ASTM

Material : Other , PVC (Polyvinyl Chloride)

Surface Treatment : Other, Smooth

Color : White

Connection : Other, Solvent weld / Threaded

CPVC Piping System

Standard : Other, ASTM D2846, IS 15778

Material : Other , Chlorinated Polyvinyl Chloride (CPVC)

Surface Treatment : Other, Smooth, untreated

Color : Light Ivory

Connection : Other, Solvent Cement Joint

Casing Pipe

Standard : Other, IS 12818

Material : PVC

Surface Treatment : Other, Smooth Finish

Color : Blue

Connection : Other, Female Socketed

PPR Submersible pipe

Standard : Other, Industry standards for water systems

Material : Other , PPR (Polypropylene Random Copolymer)

Surface Treatment : None, Other

Color : White

Connection : Other, Flanged

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese